German luxury car manufacturer Audi's factory in the Brussels municipality of Forest is officially closing on Friday 28 February, 76 years after the first car rolled off the production line.

Audi hinted at plans to advance the halting of the Audi Q8 e-tron production at its factory in Forest last summer. It cited problems with overcapacity, adding that the Brussels plant's higher production costs. By late October, Audi confirmed it would end production of the Q8 e-tron at the plant in February 2025, moving it to its plant in San José Chiapa, Mexico.

The decision sent shockwaves through Belgium and sparked a furious response from unions. Tensions threatened to spiral out of control, and workers at the plant were locked out of the factory. Thousands of demonstrators took to the streets of Brussels to express solidarity with the Forest workforce. Meanwhile, Audi was scrambling to find a buyer, but these efforts were fruitless.

After months of uncertainty, it became final: the Audi factory in Forest would shut down on Friday 28 February.

76 years of car manufacturing

On 27 September 1948, Pierre D'Ieteren, of the eponymous Brussels-based family business, laid the foundation stone of the car factory in Forest to build cars of the American brand Studebaker. The first car rolled off the production line on 7 April 1949.

D'Ieteren later became the importer of the German Volkswagen for the Belgian market. Six years after the Volkswagen Beetle was introduced in Belgium in March 1948, the car was produced at the Forest factory as well.

The factory in 1948. Credit: Audi

At this time, around 750 employees built about 75 cars a day. The factory soon started producing other VW models. At the end of 1970, Volkswagen AG took over the plant, and the first modernisation took place.

Capacity increased, and in addition to a former Citroën factory, other surrounding areas also became part of the site, with the expansion continuing until 1991. Production was modernised and equipped with new installations. In 1997, production of the VW Passat ended, and production of various Seats started.

A Golf Volkswagen car on the assembly line of new Audi Brussels, on the day of the official launch of the Audi A3, in the former VW Forest plant in 2007. Credit: Belga/ Benoit Doppagne

The first Audi (the A3 model) rolled off the production line in 2004. By this time, the factory employed approximately 5,300 people. However, in 2006, a closure loomed over the plant as Volkswagen AG decided to move production of the Golf and Polo models to German branches.

But in 2007, Volkswagen subsidiary Audi took over the factory and renamed it ‘Audi Brussels N.V./S.A.’ A new building for the production of car bodies was built in Brussels. In 2010, the Brussels plant was the only Audi factory to start production of the new Audi A1.

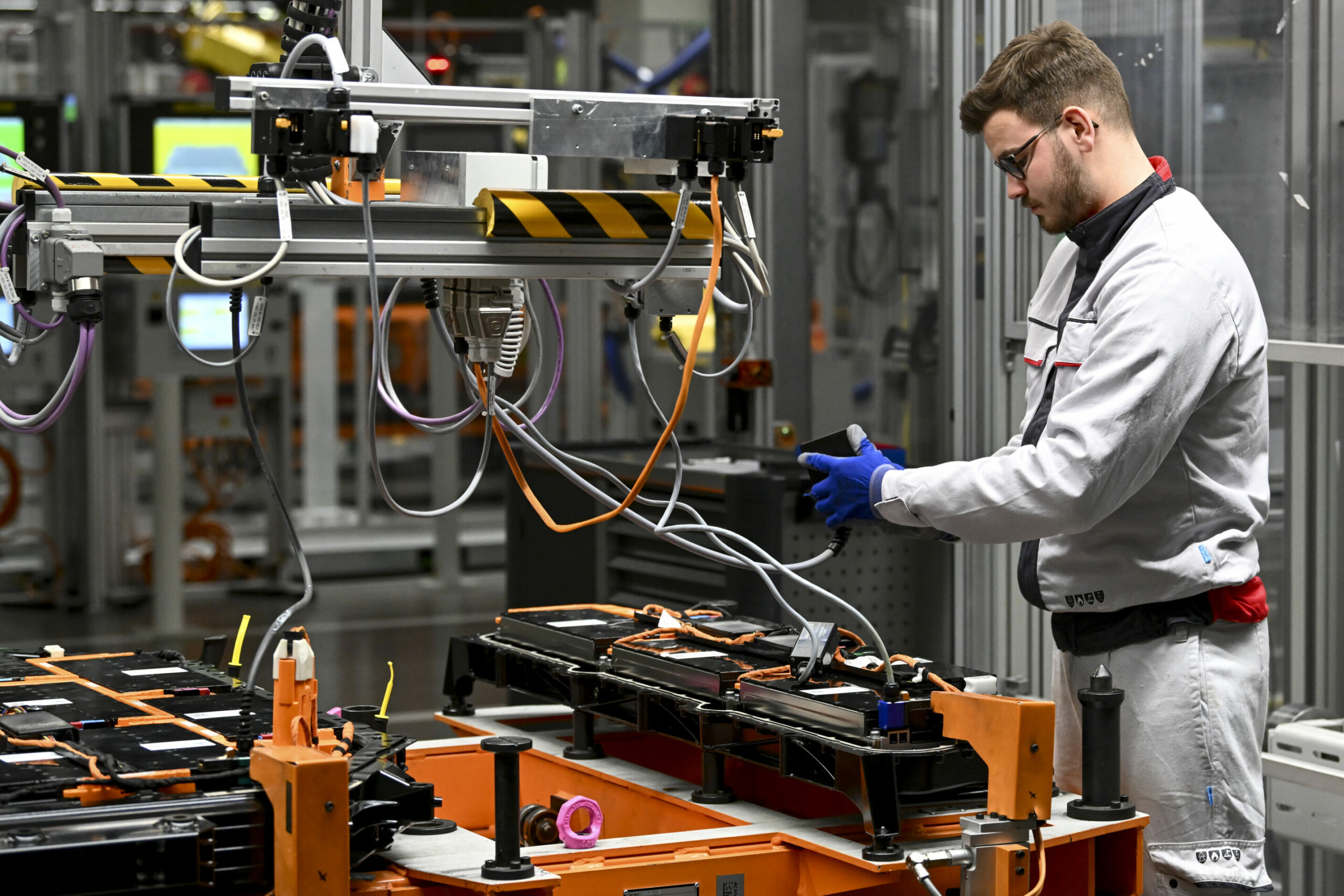

The start of production of the Q8 e-tron and Q8 Sportback e-tron in December 2022. Credit: Belga/ Dirk Waem

Dark clouds appeared again in early 2016 when Audi announced that the new A1 model would be built at its plant in Martorell, Spain in 2018. However, Audi Brussels was then asked to take the lead in electrification, with the series production of the Audi e-tron, the brand's first fully electric SUV, starting in 2018.

Production of the Q8 e-tron starts in 2022 and in 2023 the factory is adapted to also build the electric Q4 e-tron model.

Finding new jobs

More than 3,000 direct and indirect jobs will be lost due to the plant's closure. Consultations between the unions and management about a joint redundancy plan were strained and lasted for months. In January 2025, the unions and management finally reached an agreement.

In preparation for this mass lay-off, the technology industry federation Agoria is organising a special job day on 3 April in Brussels, in collaboration with employment agencies Actiris, VDAB and Forem to help workers find suitable jobs.

In the run-up to this event, it sent out a survey to the HR managers of all Agoria members to map out vacancies. "Some 350 companies responded, and 197 companies said they wanted to participate in the job day," Brieuc Janssens de Varebeke, Manager Agoria Brussels, told The Brussels Times.

More than 3,000 direct and indirect jobs will be lost. Credit: Belga/ Dirk Waem

"We asked about open vacancies linked to 13 job profiles which we identified at Audi, and received 5,000 open and suitable vacancies, mainly for engineers but also for technical profiles and in logistics." A total of 70 companies will be present on the job day, chosen based on the highest number of open vacancies.

Agoria also set up a job page to help all Audi employees and suppliers find jobs in other Belgian companies. "So there is a lot of hope, I am not concerned about the job opportunities. There are vacancies around Brussels but also closer to where former employees live, in Wallonia and Flanders."

Through similar initiatives by Agoria, more than 70% of former Van Hool [the company that is behind most buses built in Belgium, which closed last year resulting in some 1,850 job losses] employees found new jobs.

A gaping hole in Belgium's industry

A tear has also been shed over the loss of Belgium's automotive sector, with Agoria speaking of the disappearance of one of Belgium's most modern factories. "The plant was at the cutting edge in terms of automation."

This marks the latest in a series of major car factory closures. In 1997, the curtain came down on Renault Vilvoorde, which at the time employed more than 3,000 people. At the end of 2010, it was Opel's turn in Antwerp, resulting in 2,500 people losing their jobs. Four years later, the axe fell on Ford Genk, and 4,300 people became unemployed.

The Volvo factory in Ghent. Credit: Belga / Nicolas Maeterlinck

Volvo Car in Ghent is now the last major car factory in Belgium. Production at the Swedish-Chinese carmaker's site employs more than 7,000 people, making it the largest industrial employer in Flanders. It currently produces the XC40, EX40, EC40 and V60 models.

This year, the electric EX30 will also be making its debut in Ghent, providing hundreds of jobs. Volvo Cars is looking for 350 extra workers to build these vehicles. Meanwhile, the Adient group, which will supply car seats to the Ghent branch, is looking to hire around 100 new staff members. It currently employs around 600 people in Belgium.

Agoria boss Bart Steukers stressed that, despite the setback for the automotive sector posed by Audi's closure, Belgium's industry remains very strong, especially in niches such as research into new technologies, specific sensors for the automotive sector, and energy-efficient software and driving systems. "We sometimes forget that almost every car assembled in the world today contains Belgian technology or parts," he said.

What's next for the site?

The closure of the Audi site in Forest means a large factory (or the 54 hectares of land which it stands on) is becoming available on the edge of Flanders and Brussels, a strategic location. It is not yet entirely clear what exactly will happen to the existing factory and the site. Behind the scenes, people are already discussing what the plant's redevelopment could look like.

Days before the closure, Federal Defence Minister Theo Francken (N-VA) reiterated that the Audi Brussels site could serve for military production. "I really want to try to work out that dossier with Belgian and foreign companies," he said.

The Audi logo replaced the VW logo, at Forest plant in 2007. Credit: Belga/ Benoit Doppagne

Pierre Hermant of the Finance & Invest.brussels agency is responsible for the future use of the site, according to reports from Bruzz. He wants to follow the example of Ford Genk, where the closure of the factory in 2014 led to the creation of a new ecosystem of small businesses and activities.

This was mirrored by economist Ivan De Cloot, who spoke of one large company being replaced by 20 to 50 companies on the same site, stating this could be a gift for the region. "That is the conclusion we also drew after the closure of Ford Genk," he told Ring TV. "Limburg is no longer so vulnerable because it is no longer dependent on that one large employer. Instead of a mammoth factory, there is now a new ecosystem of small new activities."

In any case, the full redevelopment of the site is expected to take up to ten years.