The carmaker Audi is considering halting production at its site in Forest, southwest Brussels. But it isn't only some 3,000 jobs that hang in the balance. The plant that today makes vehicles for the German brand is a pillar of Belgium's automotive history and its potential closure would be a symbolic blow to Belgian industry more widely.

Not only an important economic hub in the Capital Region, the historic Forest site has shaped a sector that has flourished over the past century. The factory's skilled labour force has produced millions of cars since it was first built by the industrious D'Ieteren family in 1948.

Before the first World War, Belgium counted some 200 different car manufacturers. Three quarters of cars produced were exported – arguably making Belgium one of the greatest car producers at the time.

But in more recent decades carmakers have struggled with rising costs and increased competition, eroding the industry that once was so prominent. Today just two major players are still manufacturing in Belgium and the industry is sliding closer to extinction as Audi weighs up its future in Brussels and considers moving production of the Q8 e-tron and Q8 Sportback e-tron models to Mexico.

Production of the Audi e-tron at the Audi Brussels plant, in Vorst-Forest, Brussels, Wednesday 10 November 2021. Credit: Belga / Eric Lalmand.

D'Ieteren: A bastion of Belgian manufacturing

The cornerstone for the Forest manufacturing plant was laid by the D'Ieteren family in September 1948, with the first car rolling off the production line just a few months later in April 1949.

D'Ieteren is a family business older than the Belgian State, having started coach building more than 200 years ago. The company has been listed on the Brussels Stock Exchange for almost a century. In 2023 it generated a cool €5.298 billion in revenue.

In the 1930s, it began distributing US car brands like Studebaker, Pierce-Arrow and Auburn in Belgium. Soon it turned to assembling vehicles within Belgium to avoid the hefty import taxes on cars. The Forest site was first built to manufacture Studebakers, which would go on to become the third most popular American car in Belgium, behind Ford and Chevrolet.

A picture from January 1963 of an Avanti model Studebaker. Credit: Belga Photo Archives

Catering to the European demand for smaller cars than in the US, the plant started to assemble Volkswagens alongside Studebakers from 1954, after the D'Ieterens secured the sales rights for Volkswagen in Belgium. By this time, the Brussels plant sprawled over some 314,000 square metres, with a workforce of more than 750 people producing around 75 cars every day.

By the 1960s, Studebaker was facing financial difficulties and concentrated its efforts on domestic production in the US. So the Forest plant increasingly focused on producing Volkswagens. D'Ieteren's deal with Volkswagen would prove to be hugely successful: over the next two decades the plant produced over 835,000 cars – 95% of which were Beetles.

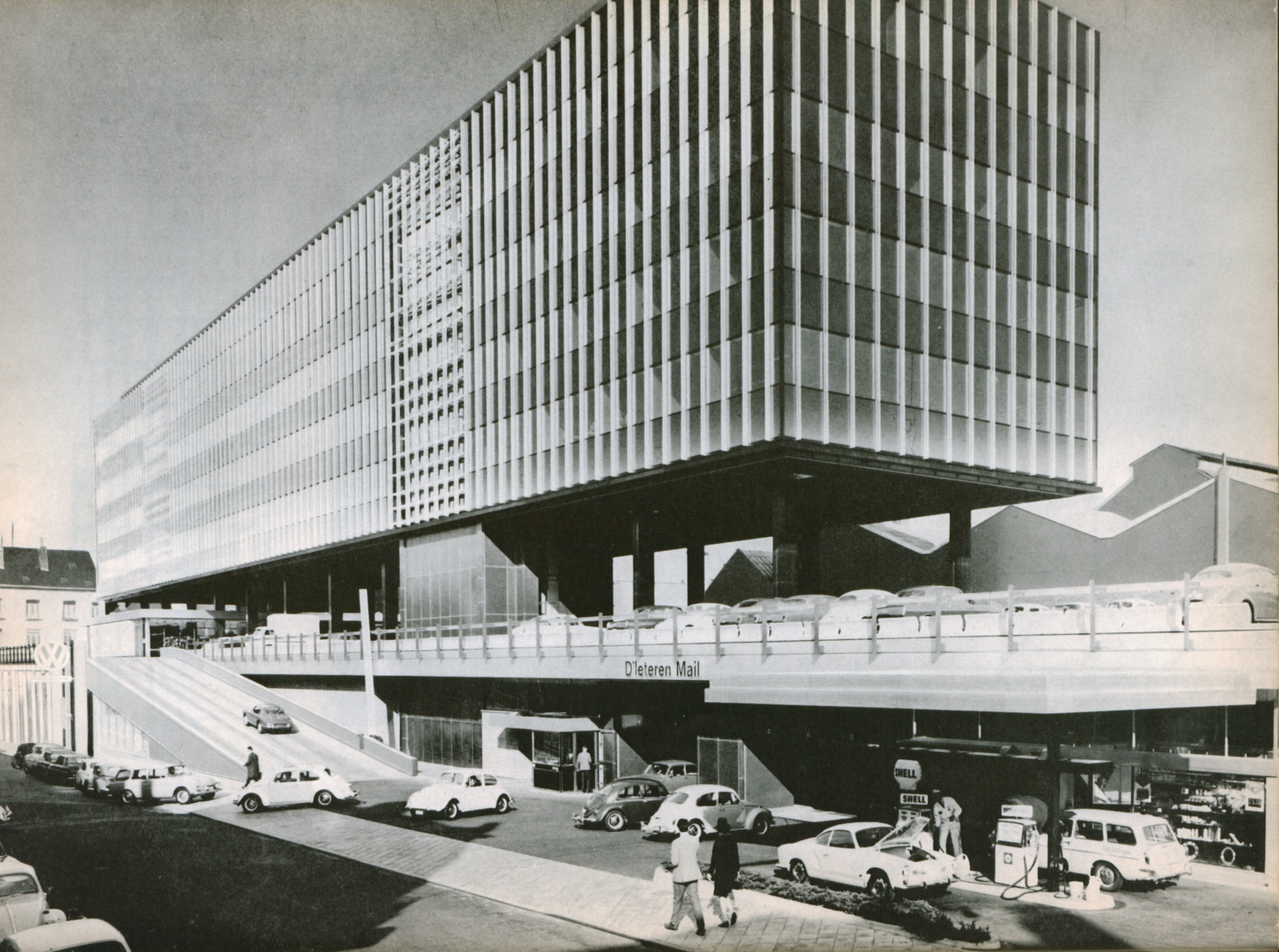

But the Forest site is not the only D'Ieteren building that has become part of Brussels history: the group's brutalist headquarters, built in the 1960s in the Châtelain district of Ixelles, was added to the Brussels protected heritage list earlier this year.

The D'Ieteren site in Ixelles. Credit: urban.brussels

Volkswagen steering production

The Forest factory was sold to Volkswagen in 1970, although the D'Ieteren Group remains the Belgian distributor for Volkswagen brands (such as Volkswagen, Audi, Škoda, SEAT, Lamborghini, Bentley and Bugatti) to this day.

By 1974 the site's workers had assembled one million Volkswagen Beetles. However, with demand for the iconic model declining, the plant produced its 1,143,464th and final "bug" in 1975. Thereafter, the Forest site produced Volkswagen's new Passat model, as well as other models like the Golf, Polo and Lupo.

By the 2000s, around 200,000 cars a year were produced each year at Forest, most of them Golfs. But with sales falling in 2006, the bombshell news broke that Volkswagen was withdrawing from Belgium to concentrate production in its German plants.

More than 3,500 roles were on the line, of the roughly 5,000 total who were working in Forest at the time. Political and union pressure grew to find a solution that would save jobs. In 1997, the Belgian automotive industry had faced the sudden closure of the Renault plant at Vilvoorde, a move which cost more than 3,000 jobs and was condemned by workers and politicians, who felt that the legal procedures concerning factory closures had been ignored.

The episode led to the development of the "Renault Procedure" which remains part of Belgian law today. It imposes a mandatory consultation period when an employer plans to proceed with a collective redundancy.

After announcing its withdrawal from the Forest plant in 2006, Volkswagen said it would compensate for the loss of the Golf by producing a different Audi model in Brussels. However, the company said it would need "public support" for the investment, as well as improved efficiency from its workforce, moderation of pay, and additional hours.

Renault workers leaving the cafeteria after the announced closure of the factory in 1997. Credit: Olivier Matthys /DAP (c) Belga photo

Audi takes the wheel

The plant was renamed "Audi Brussels" in 2007 and focused on producing the Audi A1. Towards the end of 2010, Forest produced its 7 millionth car, and prospects for the business were good despite a difficult economic situation overall for the European car industry.

By 2016, the plant was re-equipped to produce Audi's electric SUV e-tron models, which started rolling off the line by 2018. In 2021 Audi celebrated the eight millionth car leaving the factory, with Belgian Prime Minister Alexander De Croo joining the festivities.

But three years later, sales of luxury vehicles have nosedived as government subsidies end and in the face of competition from Tesla and Chinese models. Audi has announced plans to restructure operations, possibly halting production in Forest altogether. Doing so would result in the dismissal of around 1,500 Audi staff in October, and a further 1,100 by 2025 (according to reports by L'Echo).

Prime Minister Alexander De Croo, Audi Brussels General Director Human Resources Erik Prieels (C) and Audi Brussels CEO Volker Germann (2R) pictured during a meeting between the Federal Government and the direction of the Audi Brussels automobile plant, Tuesday 16 July 2024. Credit: Belga / Nicolas Maeterlinck.

This is despite the best efforts of the Belgian Government, with Prime Minister De Croo launching a rescue plan in April. Belgium has lost at least 30,000 jobs in the automotive industry in the past 30 years, with the notable closures of Renault in Vilvoorde, General Motors in Antwerp and Ford in Genk.

If the Audi Brussels closes, Volvo's site in Ghent would be the only large car factory left in Belgium. Almost 7,000 people work at the plant and more than 230,000 vehicles were produced there last year.

As Audi workers unions are due to meet with the Brussels Minister for Employment Bernard Clerfayt on 20 August, only time will tell if their jobs, as well as the long tradition of car-making in Brussels, can be saved.